Learnings + Future Work

The importance of planning ahead and in depth cannot be overstated because knowing which steps need to be adjusted with a change in the overall project makes everything easier.

I discovered an interest in exploring the intersection between engineering and art.

Take time for yourself when doing a project because latent progress is being made. Being in lab or studio is not always the most prductive.

Results

I am really happy with how the Wallflower came out! During the assembly I was worried about pieces fitting together as the petals had an organic shape.

I would be interested in making some of the components on the CNC instead of sandcasting as I think I could get higher precision and more detail.

Development Process

CAD

My CAD abilities greatly improved through this process as I learned about organic meshes to create organic shapes like the petals and leaves. I also had to think about draft angles and run flow simulations for the casting process.

This was the first time it was easier for me to translate my ideas using CAD rather than sketching.

Manufacturing

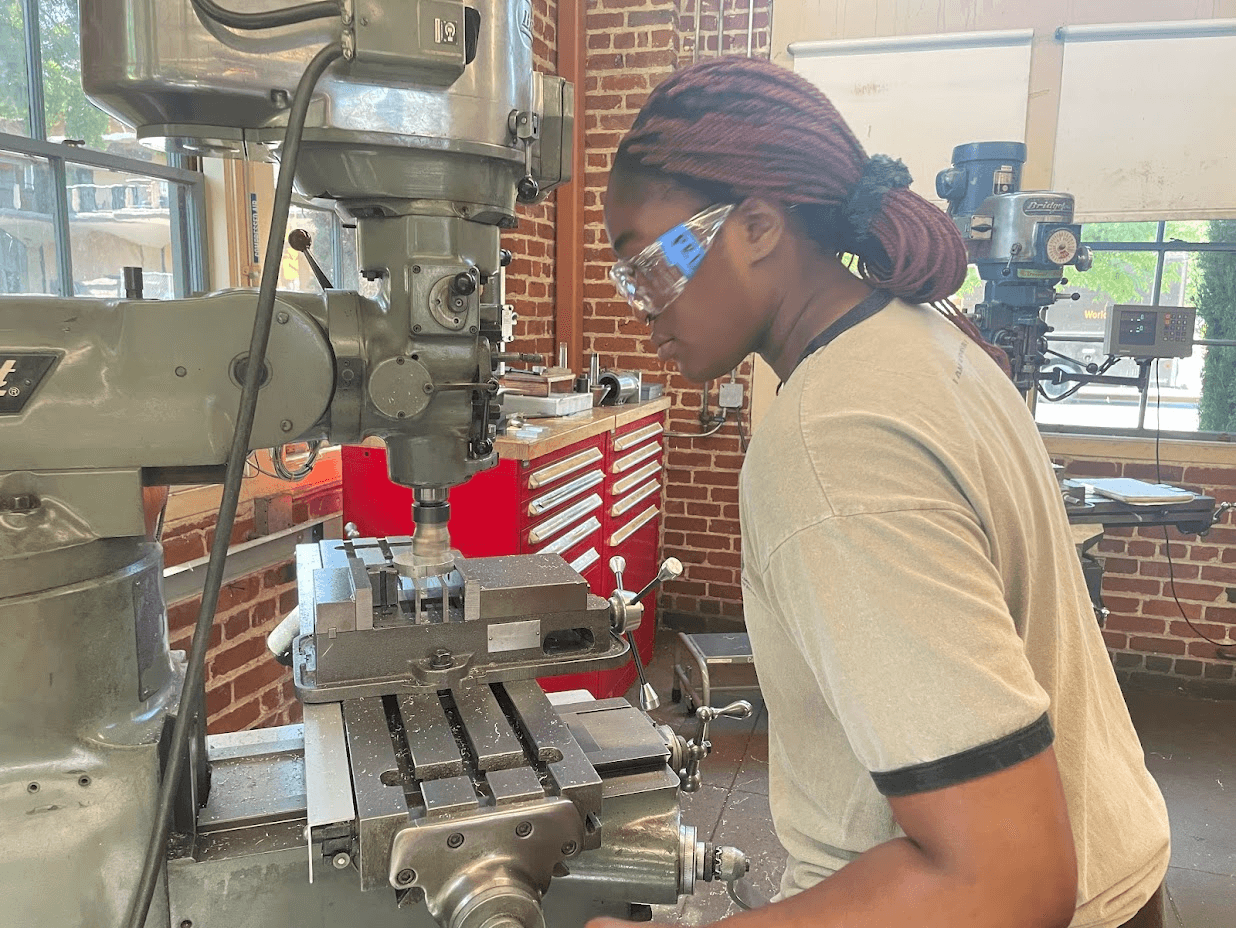

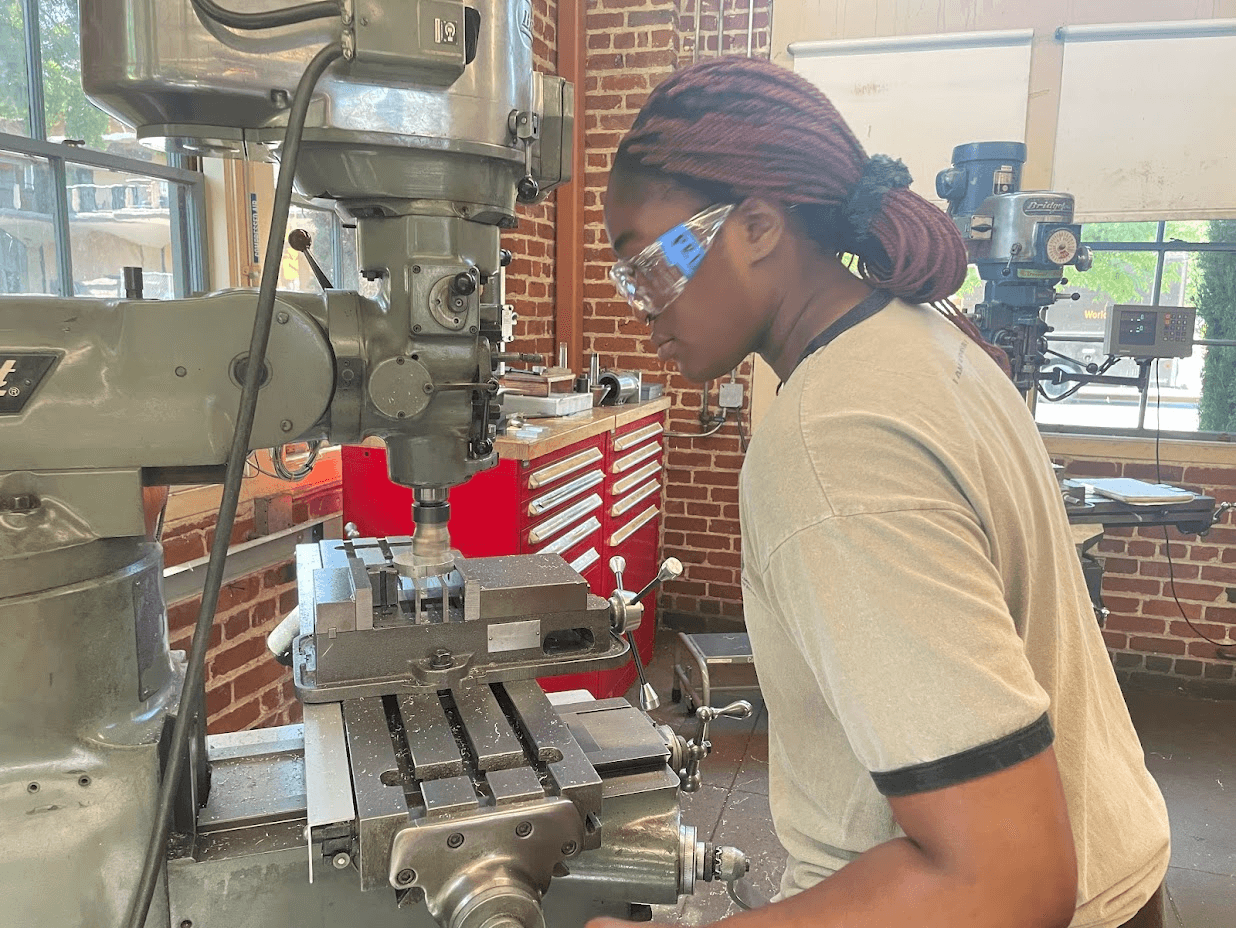

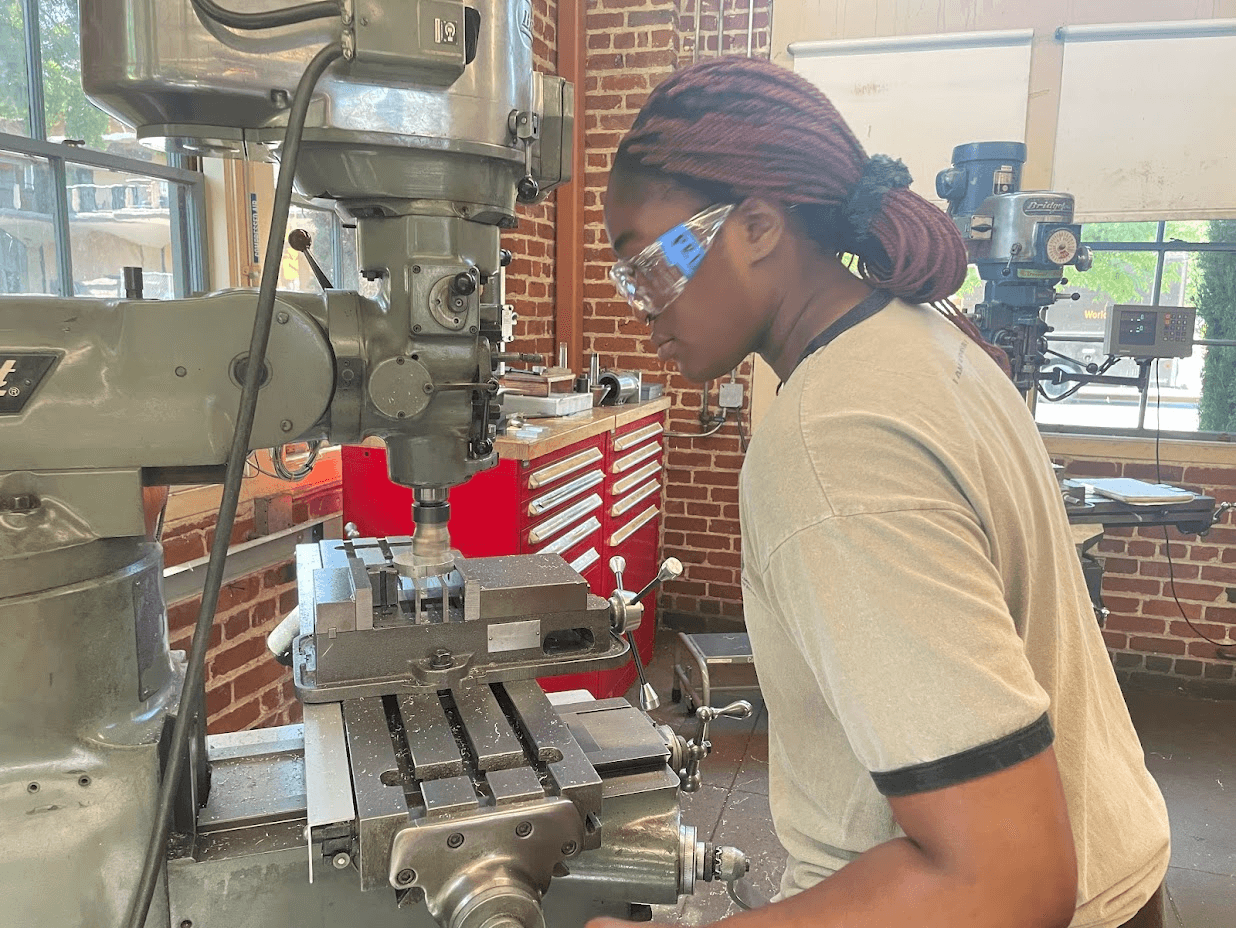

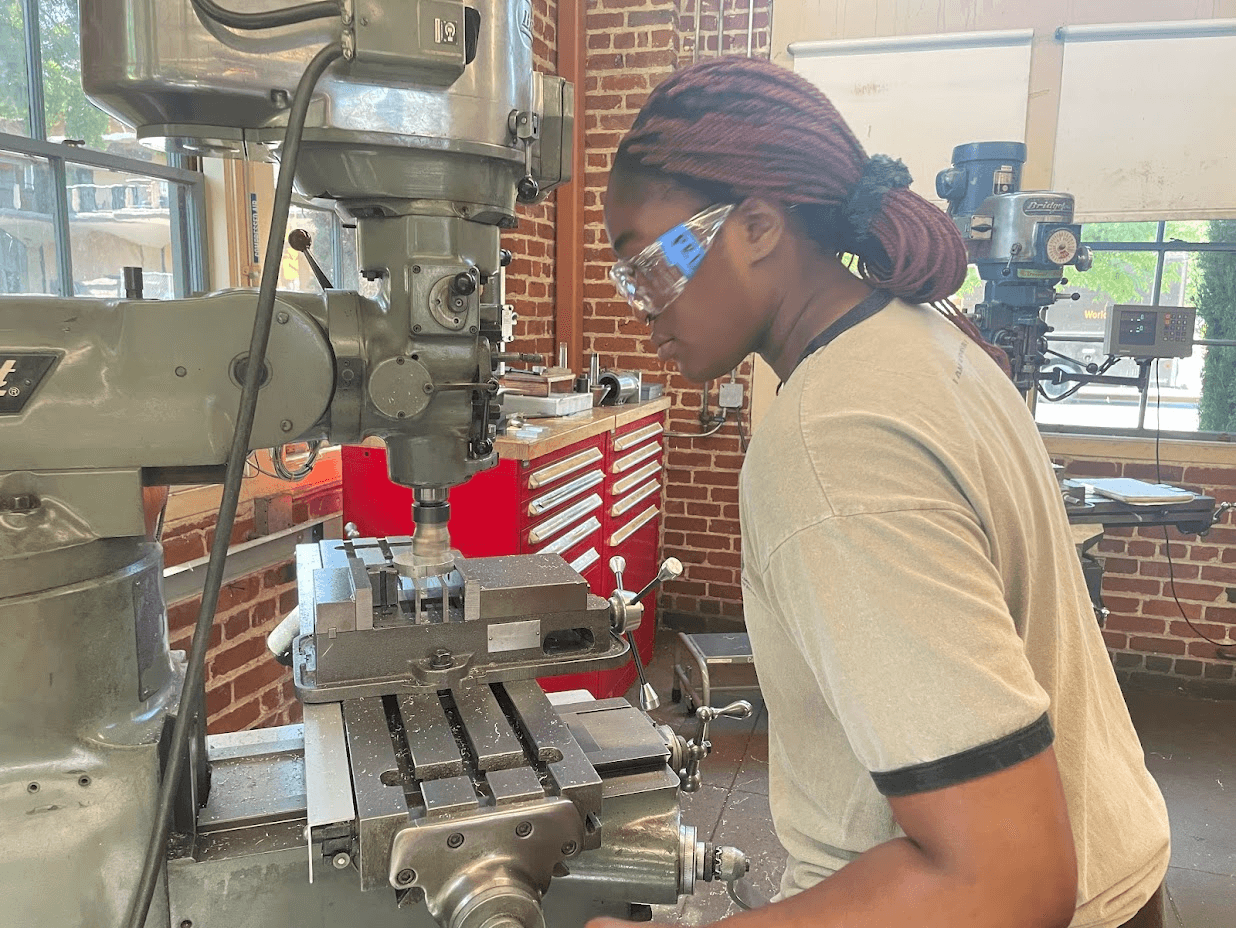

In this project I used 4 processes: sand casting, milling, turning on the lathe, and sheet metal bending.

A hard part in using so many fabrication methods is ensuring that they fit together in the end, especially with the lack of precision in casting and sheet metal bending.

Wallflower

Wallflower

Ideation

I narrowed down to three pieces: a footrest, a technology stand, and a flower shaped ramen storage rack.

I ended up combining and blending aspects of them into something new, the Wallflower. I was inspired by the flower form, specifically Jasmine, but felt that tech storage was a more useful purpose.

Given the limited counter space available in dorm rooms, I moved toward the wall and designed a product that would work as both decoration and storage.

I narrowed down to three pieces: a footrest, a technology stand, and a flower shaped ramen storage rack.

I ended up combining and blending aspects of them into something new, the Wallflower. I was inspired by the flower form, specifically Jasmine, but felt that tech storage was a more useful purpose.

Given the limited counter space available in dorm rooms, I moved toward the wall and designed a product that would work as both decoration and storage.

Context

In this project, I wanted to think about the materiality of metal. I wanted to either create contrast by mimicking nature and organic shapes out of something so rigid or lean into the geometric nature of it.

Context

In this project, I wanted to think about the materiality of metal. I wanted to either create contrast by mimicking nature and organic shapes out of something so rigid or lean into the geometric nature of it.

Development Process

CAD

My CAD abilities greatly improved through this process as I learned about organic meshes to create organic shapes like the petals and leaves. I also had to think about draft angles and run flow simulations for the casting process.

This was the first time it was easier for me to translate my ideas using CAD rather than sketching.

Manufacturing

In this project I used 4 processes: sand casting, milling, turning on the lathe, and sheet metal bending.

A hard part in using so many fabrication methods is ensuring that they fit together in the end, especially with the lack of precision in casting and sheet metal bending.

CAD

My CAD abilities greatly improved through this process as I learned about organic meshes to create organic shapes like the petals and leaves. I also had to think about draft angles and run flow simulations for the casting process.

This was the first time it was easier for me to translate my ideas using CAD rather than sketching.

Manufacturing

In this project I used 4 processes: sand casting, milling, turning on the lathe, and sheet metal bending.

A hard part in using so many fabrication methods is ensuring that they fit together in the end, especially with the lack of precision in casting and sheet metal bending.

Project Type:

Individual Class Project

Timeline:

10 weeks

The Wallflower is a wall-mounted headphone stand. I took inspiration from the jasmine flower when creating this, especially because my middle name is Jasmine! This was created using the processes of sand casting, turning on the lathe, milling, and sheet metal forming.

The Wallflower is a wall-mounted headphone stand. I took inspiration from the jasmine flower when creating this, especially because my middle name is Jasmine! This was created using the processes of sand casting, turning on the lathe, milling, and sheet metal forming.

Key Skills:

Product Design, Machining, Manufacturing Processes

Key Skills:

Product Design, Machining, Manufacturing Processes

Results

Learnings + Future Work

I discovered an interest in exploring the intersection between engineering and art.

The importance of planning ahead and in depth cannot be overstated because knowing which steps need to be adjusted with a change in the overall project makes everything easier.

The importance of planning ahead and in depth cannot be overstated because knowing which steps need to be adjusted with a change in the overall project makes everything easier.

Take time for yourself when doing a project because latent progress is being made. Being in lab or studio is not always the most prductive.

I am really happy with how the Wallflower came out! During the assembly I was worried about pieces fitting together as the petals had an organic shape.

I would be interested in making some of the components on the CNC instead of sandcasting as I think I could get higher precision and more detail.

Timeline:

10 weeks

Project Type:

Individual Class Project

The Wallflower is a wall-mounted headphone stand. I took inspiration from the jasmine flower when creating this, especially because my middle name is Jasmine! This was created using the processes of sand casting, turning on the lathe, milling, and sheet metal forming.

Wallflower

Key Skills:

Product Design, Machining, Manufacturing Processes